Features

Machine vision laser spot with rotationally symmetric, Gaussian beam profile.- Spot diameter starting at 7 µm

- Wavelengths 635 - 828 nm

- Laser powers up to 105 mW

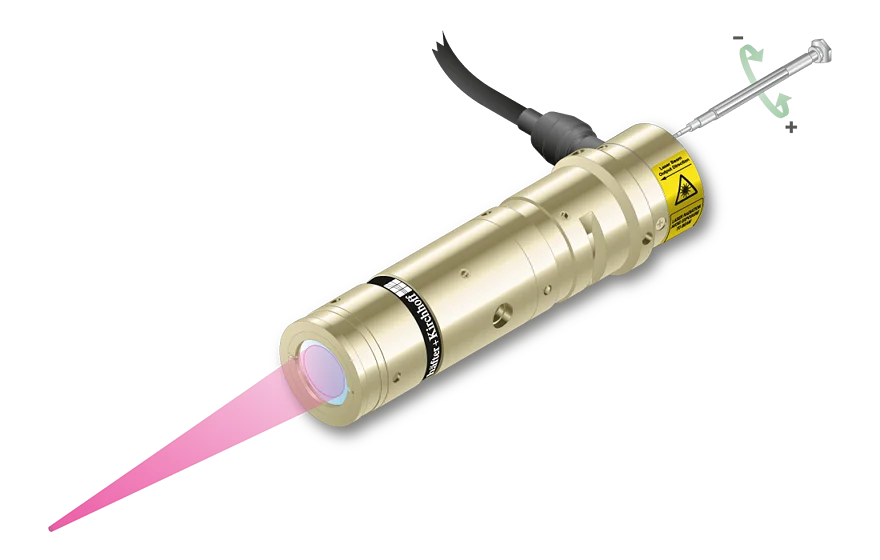

Laser Micro Focus Generator

The laser diode beam source series 13MC produces a rotationally symmetric circular laser spot with Gaussian intensity distribution.

The lasers of series 13MC are Laser Micro Focus Generators designed to produce spots with small spot size. They have a small depth of focus (in this case the depth of focus is the Rayleigh range). Laser Macro Focus Generators like the corresponding lasers of series 13MMC have common basic optical features but are designed to generate laser spots with an extended depth of focus.

The laser has integrated electronics for control of the laser output power. The output power can be controlled using the modulation input ports (TTL and analog) or manually using the potentiometer. Optionally the lasers can be equipped with RS232 serial interface for laser control and data read-out.

The working distance can be adjusted by adjusting the focus setting. Please note that the spot diameter increases proportionally to the working distance.

A fine-adjustment of the distance between laser and target is recommended for fine-focusing.

These high quality lasers can e.g. be used for machine vision applications.

What does Micro or Macro Laser mean?

Features of Laser Modules with RS232 interface

Detailed electronic features for all electronics types

Overview over all Electronics Types

Electronic features for electronics type C

Electronic features for electronics type P

Electronic features for electronics type H

Electronic features for electronics type HP

Electronic features for electronics type CS

Electronic features for electronics type PS

Electronic features for electronics type S

Electronic features for electronics type B

Line geometry, intensity distribution, definition of line length and working distance, definition of line width and machine vision applications.

Fan angle vs. semi-telecentric.

Gaussian intensity distribution and uniform intensity distribution along the laser line

Line length and working distance definition

Line width definition

When do they appear and how to prevent them

What wavelengths are available for diode based laser modules?

Straight and angled cable exit

Laser triangulation, laser light sectioning, particle measurement etc.

Laser diode based laser sources for high precision measurement and inspection systems

The laser has integrated electronics for control of the laser output power. The output power can be controlled using the modulation input ports TTL and analog (TTL only for electronics type B) or manually using the potentiometer.

Using the potentiometer you set the maximum output power of the laser. Turn the potentiometer clockwise for more power and anti-clockwise for lower power.

For all lasers with analog modulation input: The input for analog modulation allows applying an analog voltage Uanalog, which allows a linear control of the laser output power from approximately zero up to the maximum power given by the potentiometer setting.

Please refer to the manual for more details.

No, you are not allowed to take off the attachment optics. If you do so you can severely damage the laser as well as hurt yourself and others around you.

Each modification of the laser needs to be discussed with Schäfter+Kirchhoff first and is not to be done by the customer.

No, you are not allowed to take off the attachment optics. If you do so you can severely damage the laser as well as hurt yourself and others around you.

Each modification of the laser needs to be discussed with Schäfter+Kirchhoff first and is not to be done by the customer.