Generally, the applications can be grouped into one-dimensional or two-dimensional measuring tasks. For one-dimensional applications, the measured result is extracted from the pixel information of an individual line scan. Measurements of two-dimensional images require moving either the object or the line sensor

Camera Application:

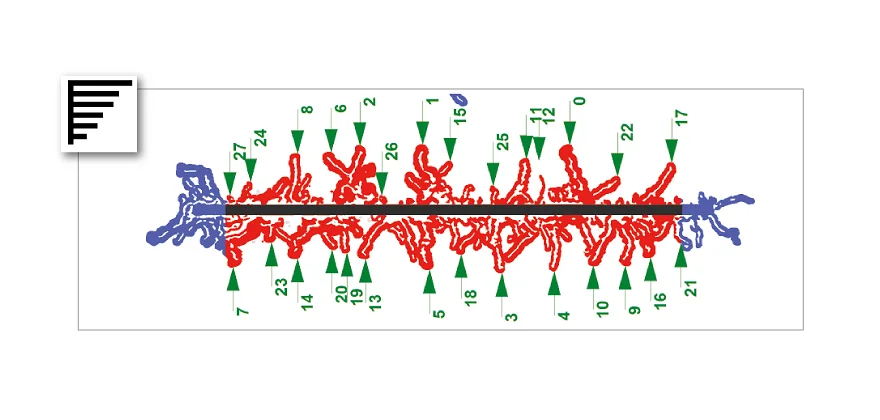

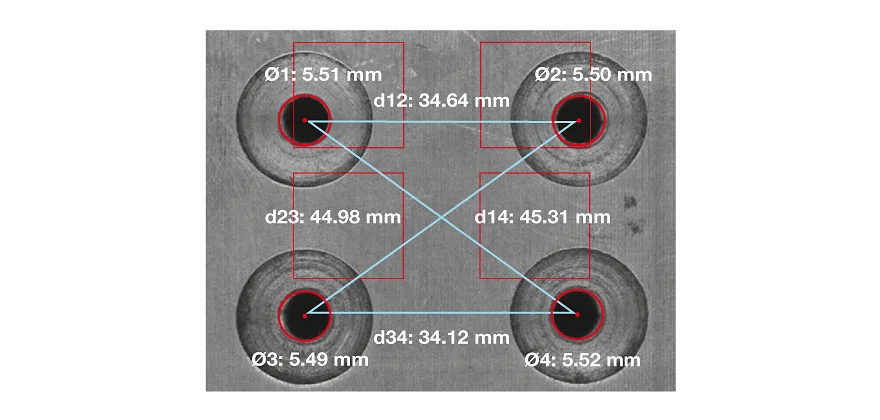

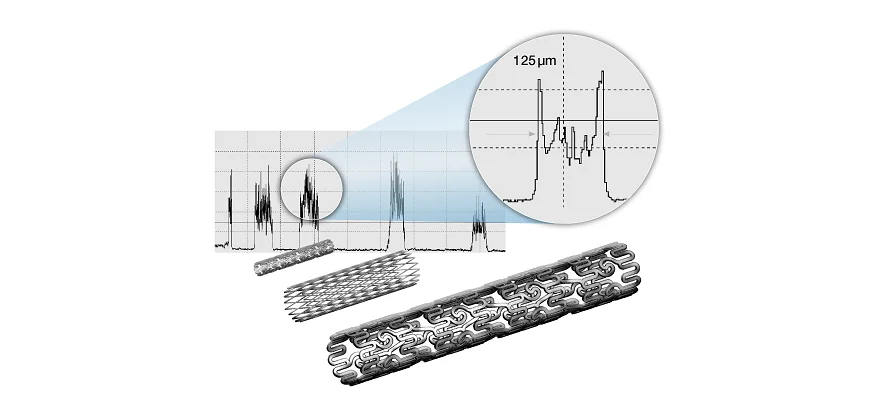

1-dimensional

- Signal generation: individual line scan

- Examples: measurement of width, rod diameter, edge positions, glass thickness.

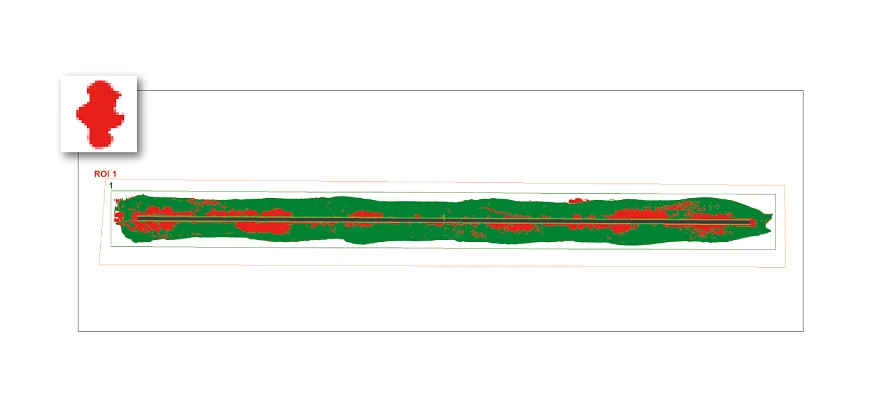

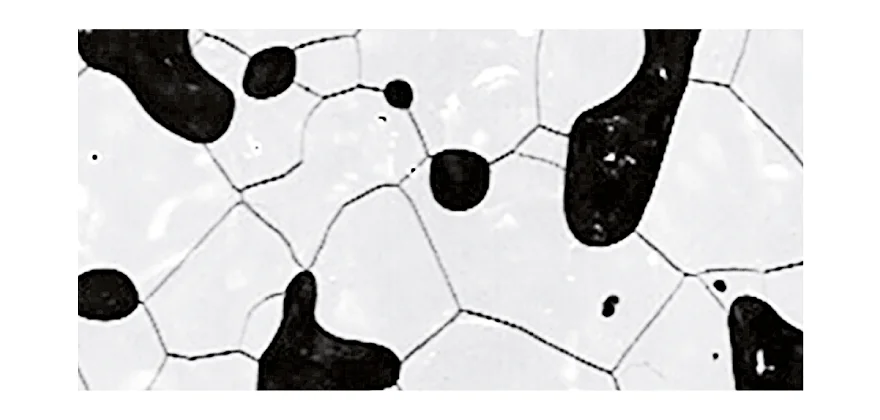

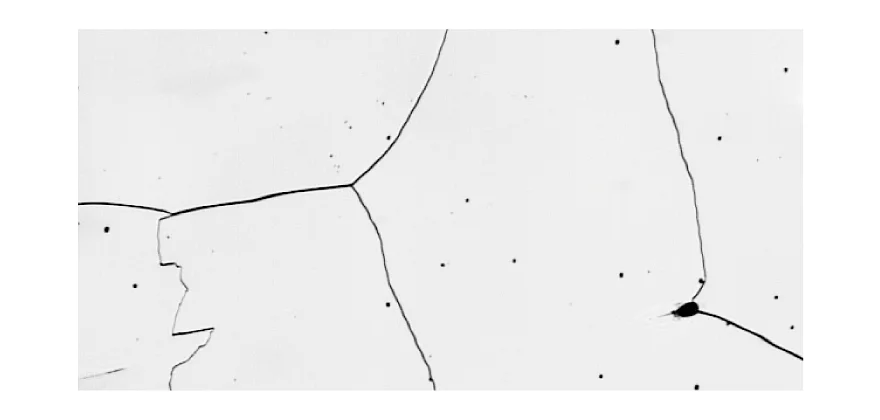

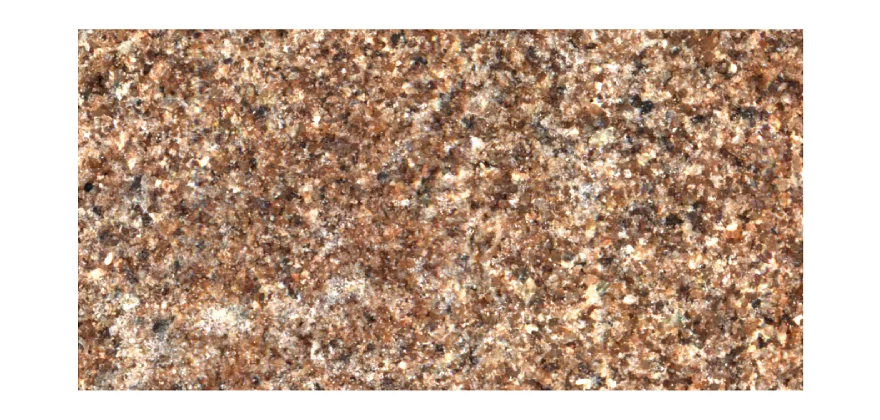

2-dimensional

- Several line scans are combined to produce a 2D image (frame)

- Examples: surface inspection, endless webbing inspection, texture analysis, scanning