The software SKan-CI offers a simple control for the camera, the translation unit and the illumination. After scanning the test sample, you have a wide range of image manipulation functions to get the best input for the analysis.

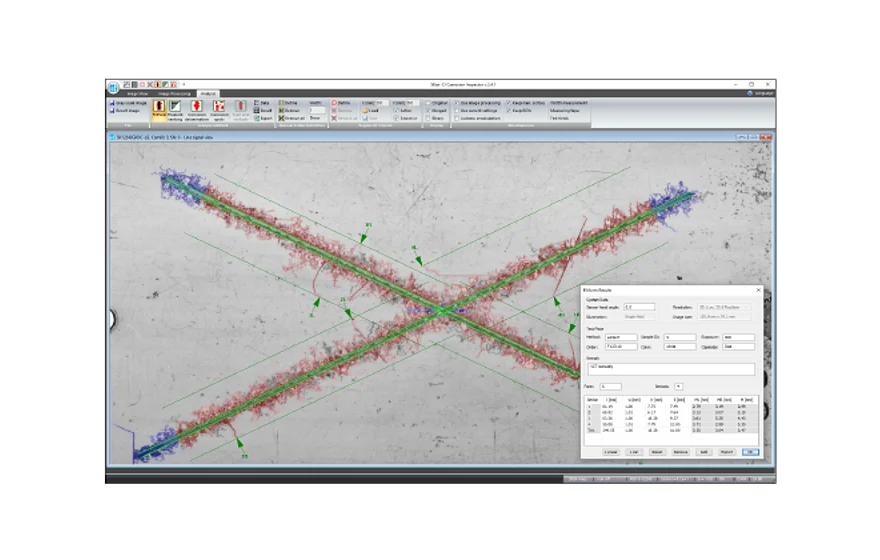

SKan-CI automatically recognizes a predefined set of scribe patterns and also automatically assigns, measures and ranks the corrosion and delamination areas, infiltration patches, filament lengths and their distribution frequency. When desired, the interactive and manual measurement of corrosive phenomena can be performed by the operator.

The SKan-CI program saves the accepted corrosion analysis results as images and tabular data, together with the treatment and analytical processing information, for retrieval, comparison and documentation.

The software supports also the offline evaluation, without a connection to the Corrosion Inspector hardware. After loading a stored image, grayscaled or color, the corrosion phenomena can be evaluated with all available methods. With it an independent reanalysis or a new evaluation is possible.

New! Trainable machine learning algorithm for difficult samples

In reality, the corrosion test panels are not always perfectly prepared. Structures and scratches in the background often directly interfere with the automatic detection of corrosion.

The latest software version includes a new feature that uses a trainable machine-learning algorithm for separating actual corrosion and background effects.

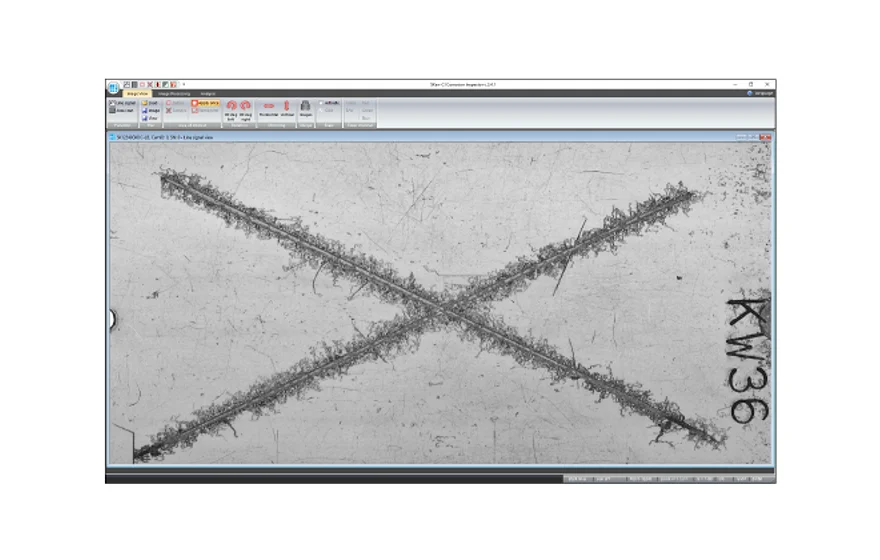

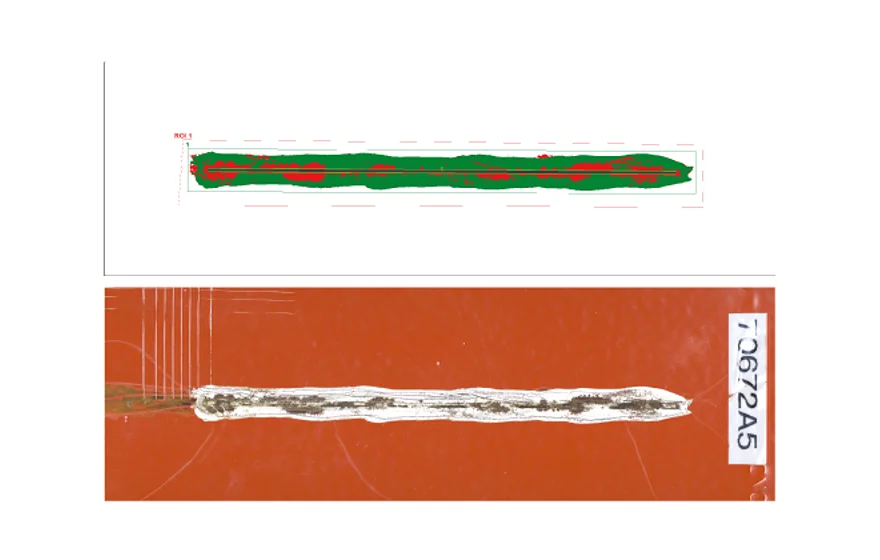

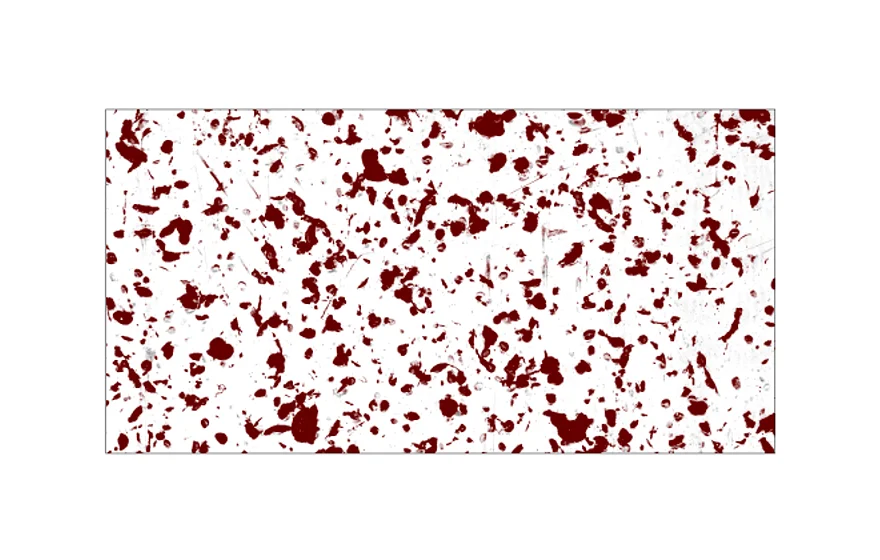

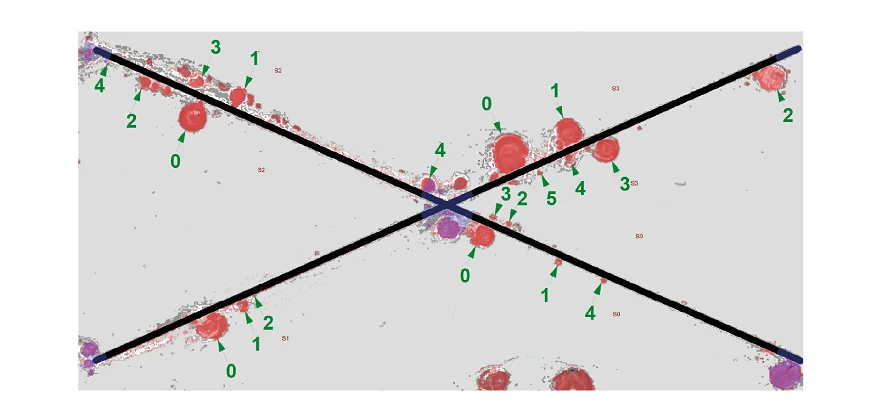

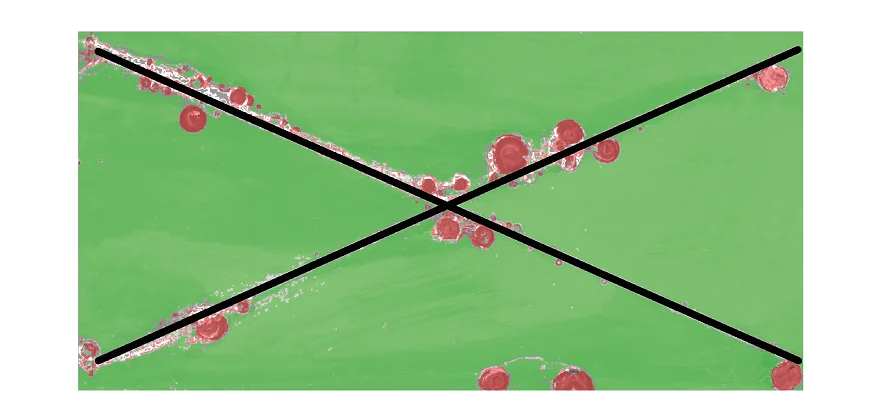

The example shows a scribed panel that has been exposed to a salt spray test. The task is to measure the size and the expansion of blisters caused by infiltrated corrosion that are close to the scribes. Due the aggressive environment, the image has a difficult background with visual smears and structures. In some cases, the blisters are barely distinguishable from the background.

Step 1: AnnotationsThe operator simply marks typical structures of interest such as background, blister and scribe areas in user-defined colors.

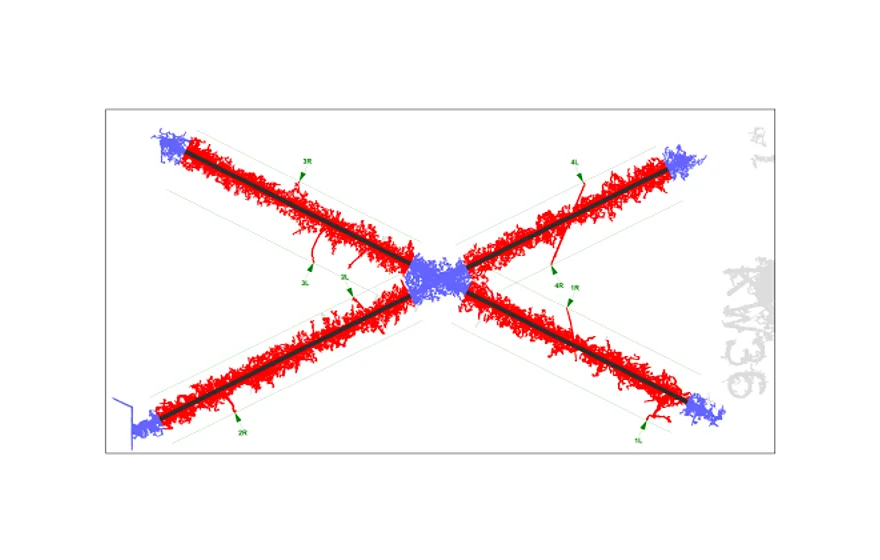

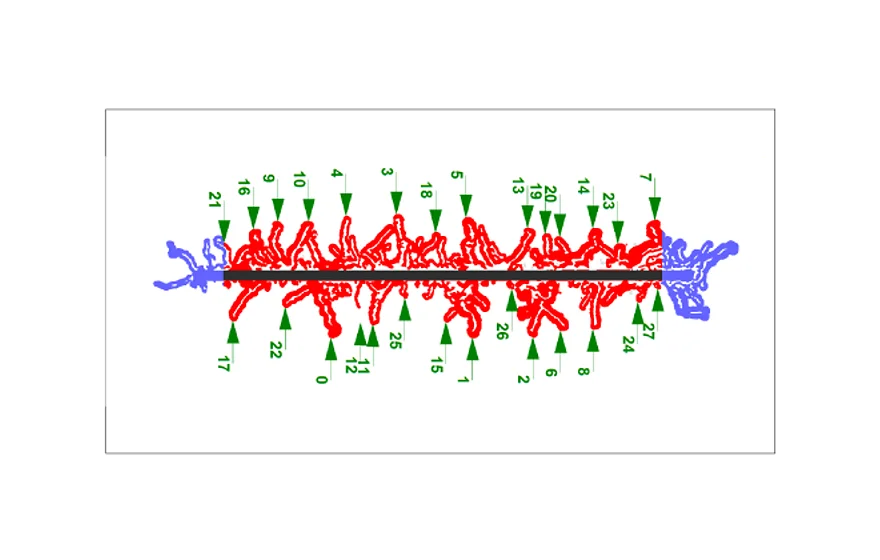

Step 2: Training the algorithmThe algorithm then assigns the background, the blisters and the scribes using the trained algorithm.

Step 3: MeasurementThe software measures the expansion and the size of the blisters. Once trained, the following panels are processed using the trained algorithm.