Features

- NEW: With trainable machine learning algorithm!

- Monochrome scanner system

- Test panel size max. 100 mm x 200 mm

- Resolution 40 microns/pixel, 650 dpi

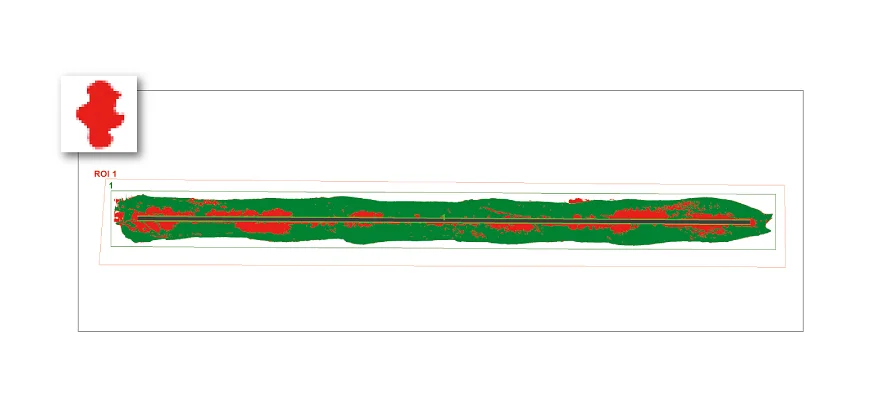

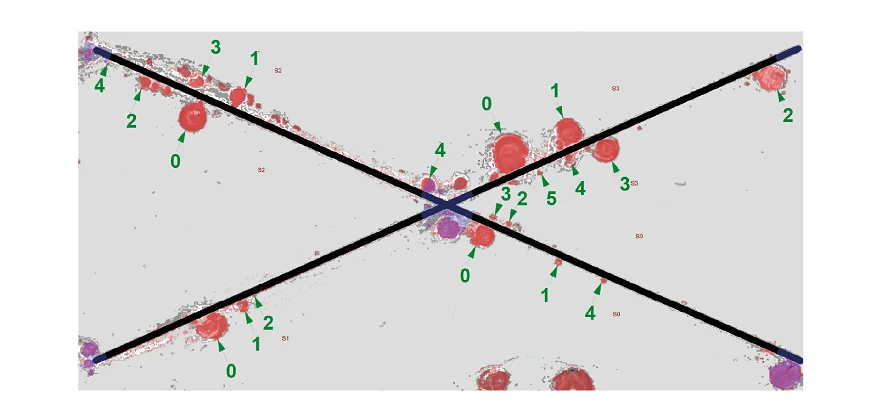

- Automatic and interactive measurement of corrosion phenomena, like area, width, filament length, red rust, delamination, multi-impact.

- Corrosion evaluations on corrosion test panels according to

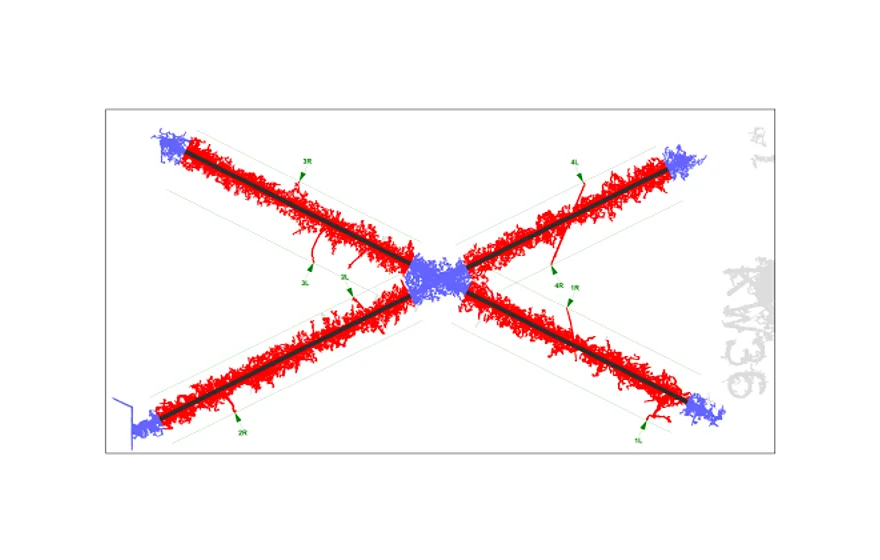

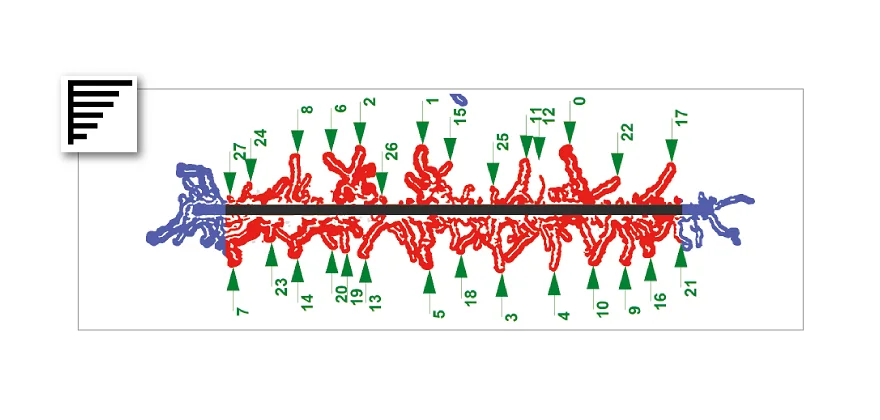

- Filiform corrosion according to ISO21227-4

- Delamination and corrosion acc. to ISO 4628-8

- Cross-cut classification according to DIN EN ISO 2409

- Edge corrosion characteristic according to MBN 10494-6

- Blistering according to DIN EN ISO 4628-2

- Stone impact resistance test according to DIN EN ISO 20567-1

- Counting of all filaments, maximum length l, r

- Evaluation according to GSB, ACT II, Qualicoat