- Corrosion evaluations on car rims or wheel segments, as well as on corrosion test panels

- Partial scanning of installed parts on cars, e.g. wheels, doors, bumpers, etc.

- Imaging and optical quality control of any kind of coatings

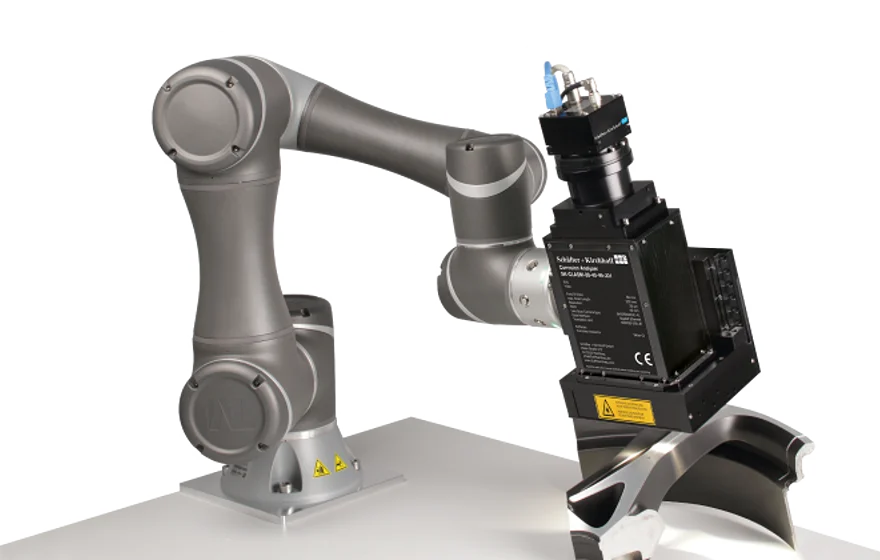

Robot-guided Line Scan Camera

Exhibition Setup

Description

Unlimited freedom with high safety

Thanks to a 6-axis robot arm, there are almost no limits to the scanning of surfaces. Whether strongly curved, slightly twisted or a flat surface - all this is no handicap for the robot arm. This great freedom is supported by intuitive operation for creating the path for the scanning process. Waypoints can be set either by hand or in an easy-to-use software interface. When using the software interface, the robot arm can be controlled with high precision in both the position and angle of the sensor head.

The operator also benefits from the high safety of the robot arm thanks to force-torque sensors that comply with the standards DIN EN ISO 10218-1 as well as the requirements of DIN ISO/TS 15066. If too much force is applied, the robot arm switches off automatically. The operator must manually confirm the safety status in order for the robot to resume its work. This ensures safe operation in cooperation with humans.

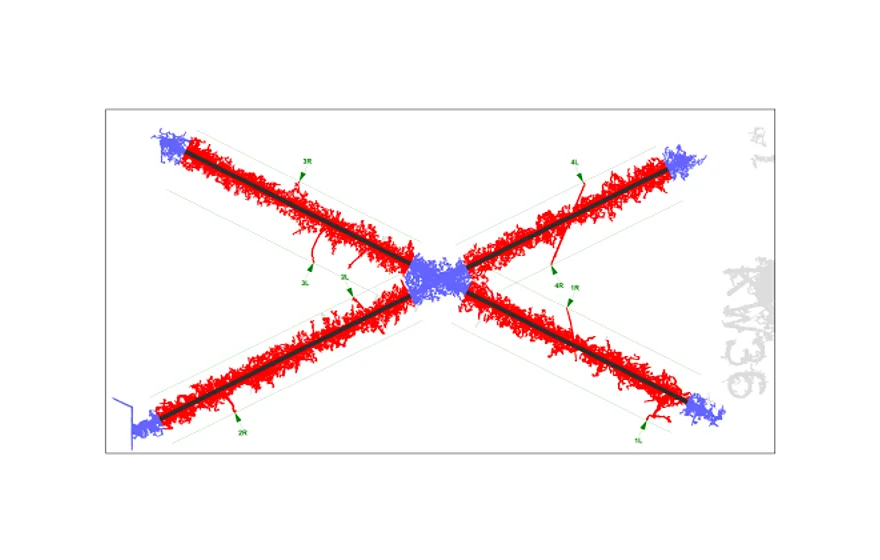

Automatic Evaluation

Automated evalution of various corrosion parameters of different scribe pattern. Among other things, the infiltration area, the average infiltration width, length and number of threads are evaluated.

Technotes

- Line Scan Camera Basics (10)

What are Line Scan Cameras? How do you create an image? etc.

- What are Line Scan Cameras?

Introduction and advantages of Line Scan Cameras

- Creating an image using Line Scan Cameras

How to create an image, definition of line frequency, and how to improve an image

- Optical resolution

Definition and comparison to conventional area cameras

- Synchronization

Reasons for synchronization and definition of different synchronization modes

- Shading correction and white balance

Why do you need shading correction and how to use white balance

- Sensor alignment

How to properly align the line scan camera sensor

- Blooming and Anti-Blooming Correction

What is blooming and how to correct it

- Spectral sensitivity

Spectral sensitivity of different line sensors

- True color imaging technologies

Color Calibration of RGB cameras

- Bright and dark-field illumination

Details about the different illumination techniques.

- Article - On the trail of rust

Evaluate corrosion test panels quickly and objectively.